Professional slip ring manufacturer

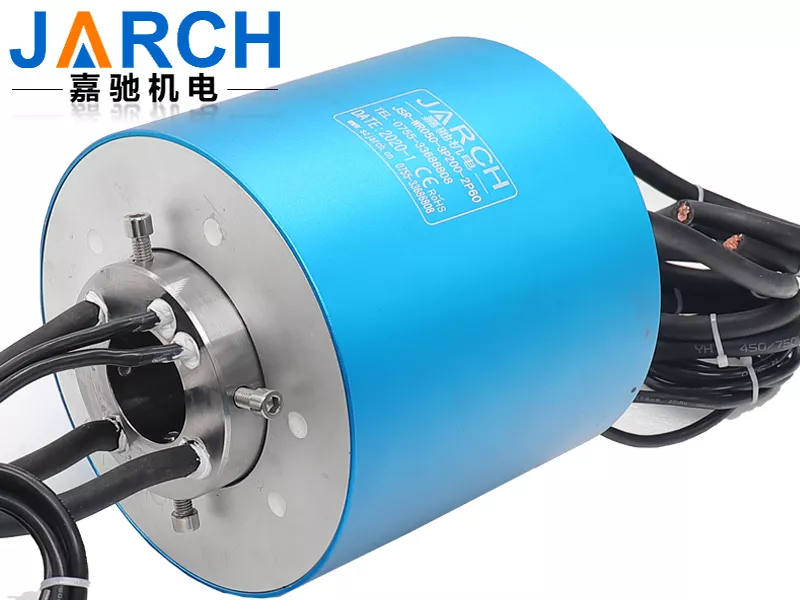

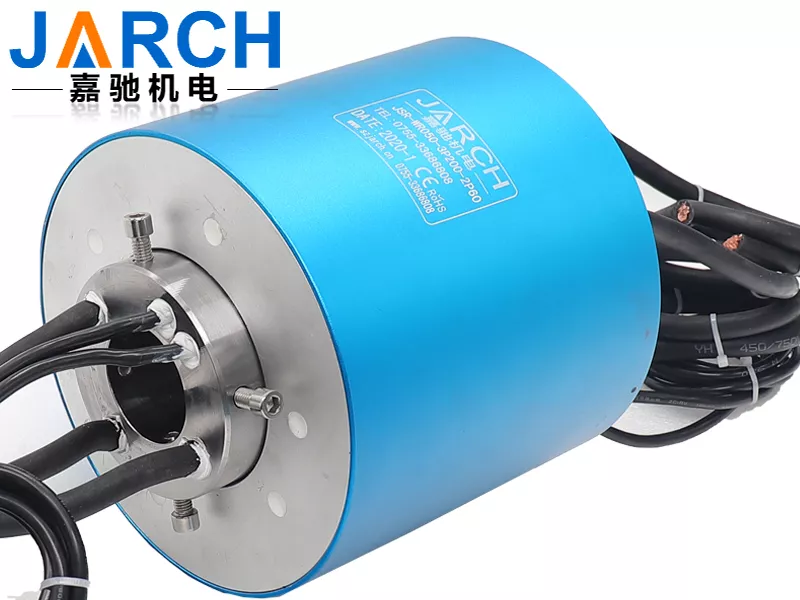

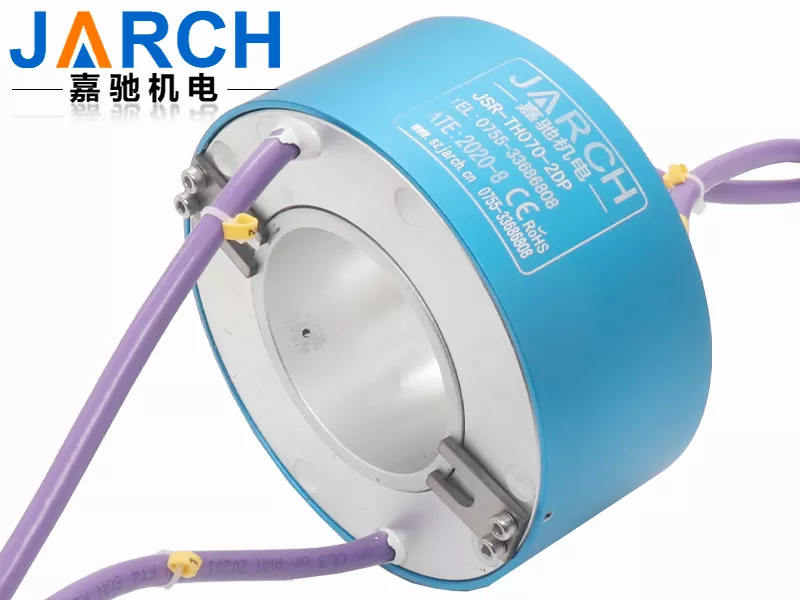

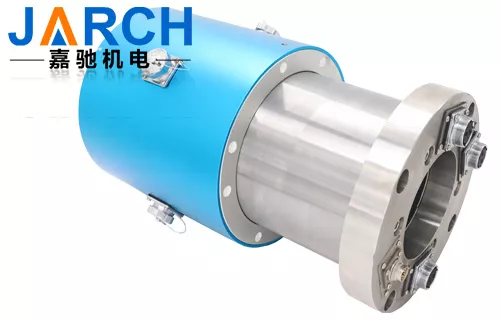

slip ring

”The latest newsGenerally speaking, there are three different specifications of conductive slip rings for shore power reel drums, including high current slip ring and low current slip ring, which are suitable for different ship shore power reel drums.

The application of conductive slip rings is more and more extensive. Many enterprises put forward higher requirements for them. Under some special circumstances, ordinary conductive slip rings are no longer suitable for conductive slip rings. Generally, there are special requirements for their materials and protection levels

The conductive slip ring, as the electrical component responsible for the rotary connection and transmission of energy and signals in modern automatic equipment, has been widely used in many automatic equipment. At the same time, with the continuous development of technology, the conductive slip ring, as an indispensable electrical component of modern automatic equipment, has been developing rapidly. How do we choose a slip ring that suits us?

Mercury conductive slip ring can not be widely used because of many other factors, such as material, price and technology...

The conductive slip ring was originally developed to prevent the wires from being wound during the use of electrical equipment. Therefore, one of the main functions of the slip ring is to conduct electricity, and the other is to rotate without winding wires. A good quality conductive slip ring must have good conductivity. The current transmission is unimpeded, the rotation is smooth, and it can rotate easily. Only when these two items are completed can more functions be developed.

The most basic conductive slip rings must be explosion-proof. The slip rings used in steelmaking must be resistant to high temperature. All conductive slip rings in electroplating industry must be able to withstand excessive current

news

- New HD High Frequency Video Combination Slip Ring Solution!!!Why does High-end Equipment Use Fiber Optic Slip Rings Instead of Standard Slip Rings? How Wide the Application Range of Mercury Slip Rings,Do You Know it?

- How to solve the problem of smoke when the conductive slip ring is in use?---The importance of using fiber brush technology for conductive slip ring,and do you know the Wind power slip ring?

- How to Choose the Model of the Slip Ring You Need? The Installation Method of the Rotating Slip Ring--Shaft or Flange?

- The difference between the old carbon brush slip ring and the new brush slip ring, what are the media transmitted by the slip ring?

- How to use disc conductive slip rings and the advantages and characteristics of mercury slip rings

- How does the slip ring realize the simultaneous transmission of multiple media? How does a slip ring work?

- Is the life of the conductive slip ring long? Why is the service life of the mercury slip ring not long?

- Is it true that miniature cap-type slip rings are widely used in anchor fish equipment? How to choose a through hole slip ring correctly?